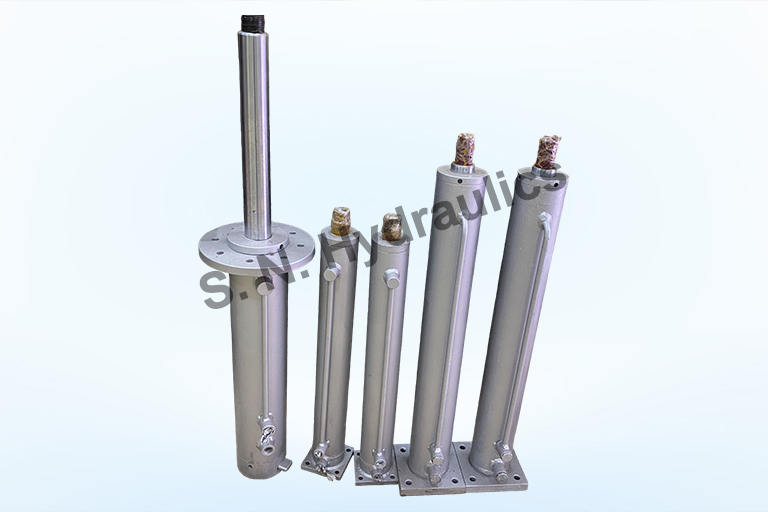

The force that the cylinder applies is transferred to the area on which it is placed by cylinder mountings. They are in charge of maintaining alignment and preventing movement that can cause fatigue failure. With flange-mounted hydraulic cylinders, the force is transmitted most effectively along the cylinder's central axis. Flange mount type are mainly used where fluid power is converted to mechanical force. The threaded steel flange design outperforms comparable welded flange type designs in terms of bending stress capability, durability, and higher shear safety features. To ensure failure-free performance, high strength bolts are assembled with hardened steel washers.

Specifications :

| Voltage | 220-240V |

| Material | Mild Steel |

| Motor Power | 2-5 HP |

| Automation Grade | Semi-Automatic, Automatic |

| Power Source | Electric, Hydraulic |

| Phase | 3 Phase |

| Capacity | Up to 2000 Ltr |

| Working Pressure | 150-300 Bar |

| Frequency | 50-60 Hz |

| Flow Rate | 300-400 Ltr/Minute |

| Max Pressure | Up to 390 Bar |

Features :

◉ Faster machine design

◉ Reduced maintenance requirement

◉ Reduced downtime

◉ Better machine and operator safety

◉ Higher productivity

Applications :

◉ Cranes

◉ Front End Loader Attachments

◉ Forklift Attachments

◉ Coal Stacker

◉ Re-claimer System

◉ Mill Relining Machines